First in the Industry to Invest in Clean CNG Mixer Trucks

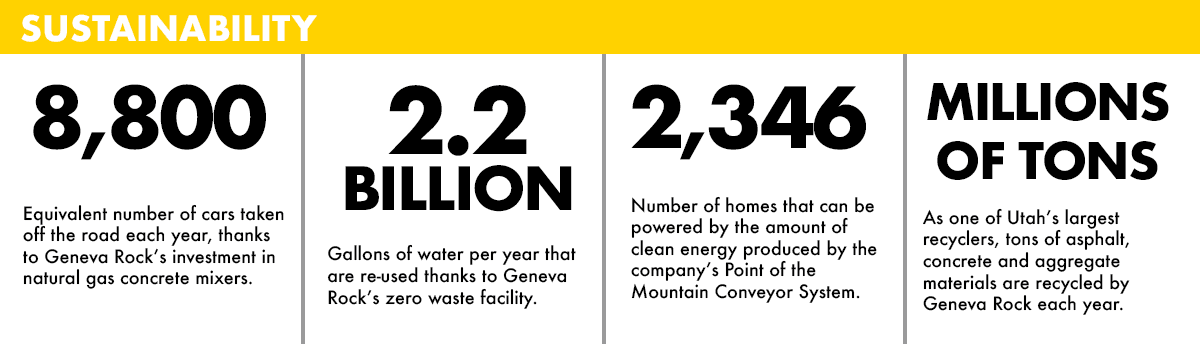

Geneva Rock Products was the first in the industry to invest over $8 million in a new Compressed Natural Gas (CNG) fueling station and fleet of 25 CNG Ready-Mix Concrete Trucks. The new cleaner-running CNG fleet has significantly lower emissions than its diesel counterparts: 50% less fine particulate matter and 90% less carbon monoxide. Geneva Rock’s investment into clean air and sustainable practices is among the largest air quality investments made by any construction company in the state of Utah. The CNG filling station and fleet are just part of the company’s $30 million clean air initiative to help improve Utah’s air quality.

In addition to this announcement, Geneva Rock donated $25,000 to the Utah Clean Air Partnership (UCAIR) to support their grants and education programs in 2017.